IMPROVED RELIABILITY OF PYRO-PROCESS WITH NON-CONTACT TEMPERATURE MEASUREMENT

HGH, a leader in infrared technology, offers innovative solutions specifically designed for kiln applications: KILNSCAN and PYROSCAN. These systems revolutionize kiln monitoring by providing detailed thermal analysis and real-time imaging, leading to enhanced operational efficiency, reduced downtime, and improved product quality.

IMPROVED RELIABILITY OF PYRO-PROCESS WITH NON-CONTACT TEMPERATURE MEASUREMENT

HGH, a leader in infrared technology, offers innovative solutions specifically designed for kiln applications: KILNSCAN and PYROSCAN. These systems revolutionize kiln monitoring by providing detailed thermal analysis and real-time imaging, leading to enhanced operational efficiency, reduced downtime, and improved product quality.

PYROSCAN

Advanced Pyrometric Imaging

PYROSCAN is a High Dynamic Range (HDR) pyrometric imaging system developed for enhanced monitoring of the flame and combustion process inside cement kilns.

PYROSCAN

Advanced Pyrometric Imaging

PYROSCAN is a High Dynamic Range (HDR) pyrometric imaging system developed for enhanced monitoring of the flame and combustion process inside cement kilns.

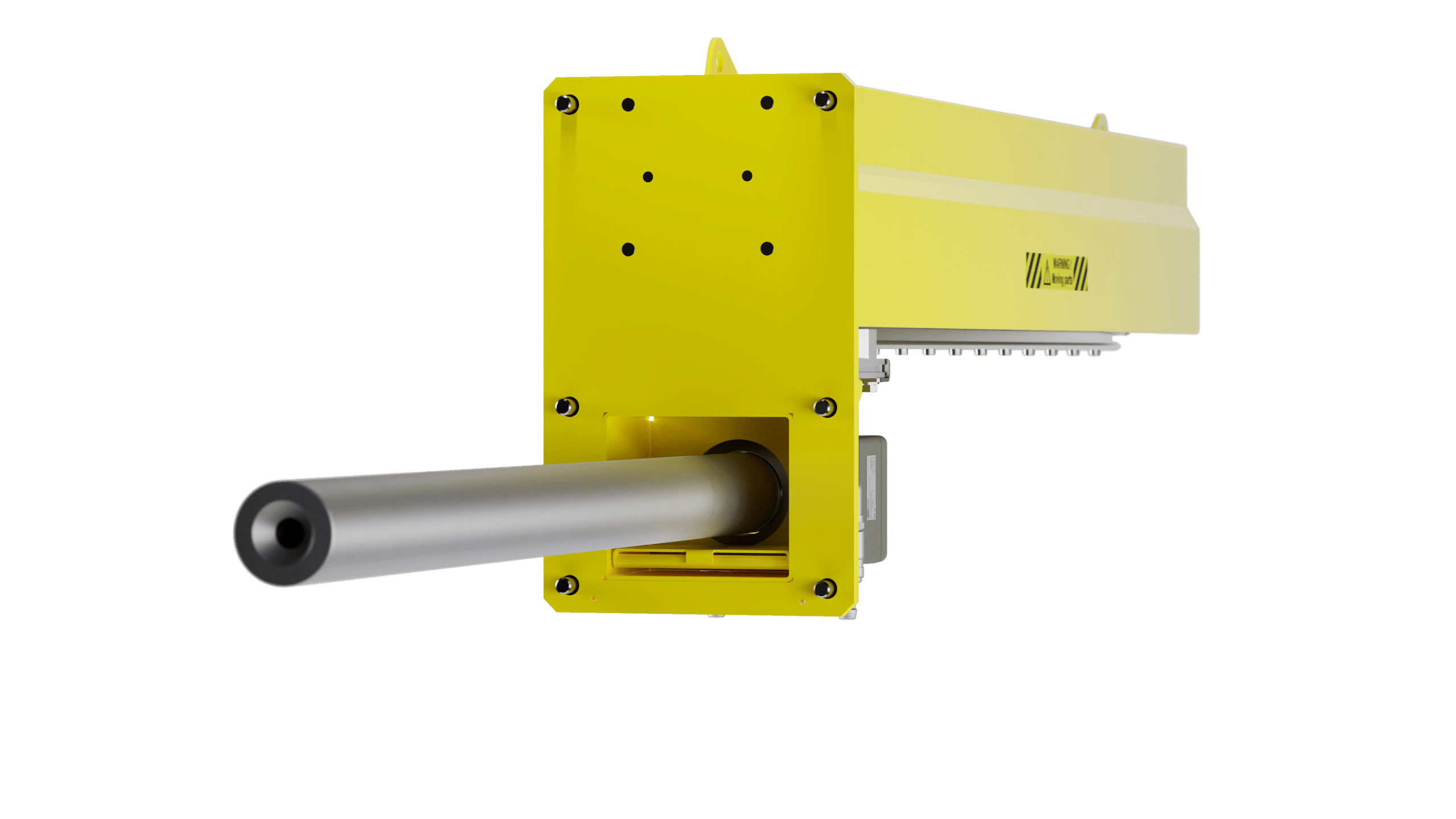

KILNSCAN

Infrared Shell Scanner & SIRCIM Software

KILNSCAN is a high-resolution thermal scanner designed to provide continuous, real-time thermal monitoring of the entire length of rotary kilns.

PYROSCAN-U

Compact Visual and Pyrometric Camera

PYROSCAN-U is an uncooled thermal camera designed to perform combustion monitoring in kiln, furnace, boiler or reactor.

KILNSCAN

Infrared Shell Scanner & SIRCIM Software

KILNSCAN is a high-resolution thermal scanner designed to provide continuous, real-time thermal monitoring of the entire length of rotary kilns.

PYROSCAN-U

Compact Visual and Pyrometric Camera

PYROSCAN-U is an uncooled thermal camera designed to perform combustion monitoring in kiln, furnace, boiler or reactor.